With the days getting shorter and the temperature dropping, winter is fast approaching. Riding in the winter not only requires a little bit of extra prep in the clothing department, but also for your bike to keep running smooth and minimize breakdowns.

Having a mechanical issue in the warmer months of the year can be inconvenient, but during the winter months it can spell disaster. Avoiding situations before they arise is the best solution, but mechanicals do happen, so being prepared to fix them quickly will ensure you’re not in a bad situation for long. Other measures for the bike can also be taken to keep you warmer as well as safer with the waning light.

Winter Maintenance – Fix it Before it Breaks!

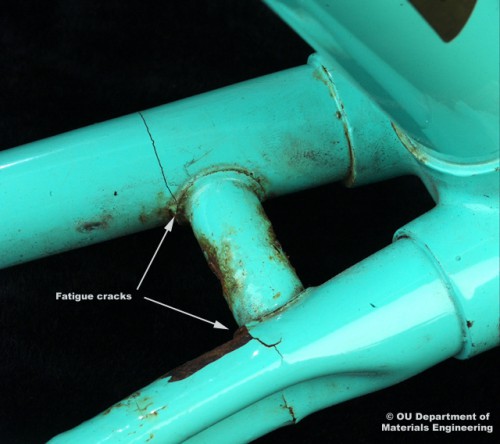

The biggest reason things break on a bike are due to over wear. Newer, well-functioning parts are very rarely going to fail unless due to a crash or some other catastrophic event. Cold temperatures, snow, ice, and grit can quickly deteriorate parts, but starting winter with a few fresh additions will help ensure that they last until spring and beyond.

Chain

With the possibility of snow as well as water spraying up and freezing in your chain along with added road grit, the chain takes a lot more stress in winter months. Start the season with a new one to minimize the risk of it breaking.

Brake Pads

In a lot of areas winter brings with it wet roads which wear down your brake pads much more quickly. This combined with the possibility of roads being slippery due to snow as well as loose sand, cinders, and grit means that you have to brake harder to slow your speed to safely navigate corners, thus further wearing down your brake pads. Start winter with a set that is dedicated to moist conditions.

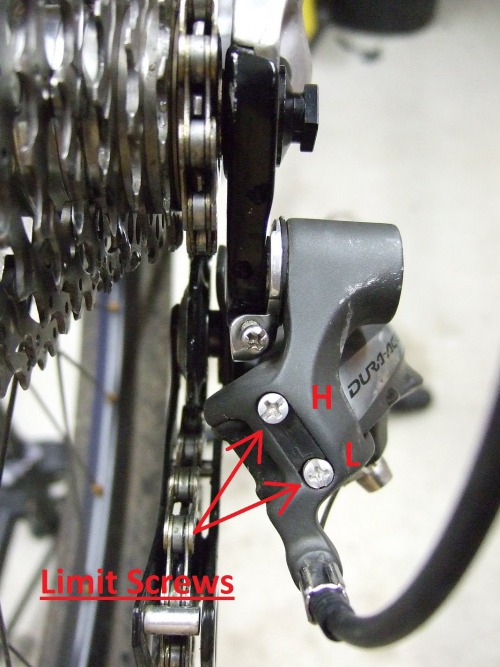

Cables/Housing

With the grit of salt, cinders, sand, and who knows what else in winter, anything that moves is going to start to experience more drag and friction. Derailleur and brake cables in particular are going to take a lot of abuse and will snap if not properly looked after. Don’t only get new cables on your bike before winter starts, but also new housing if they look worn.

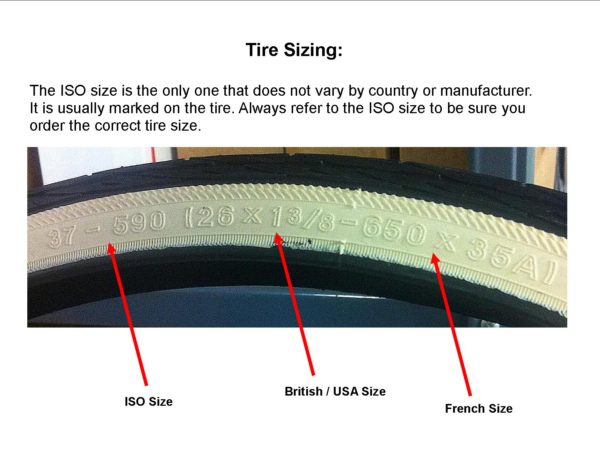

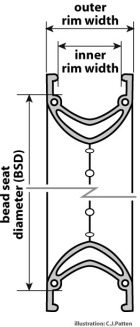

Tires

The dirt and grit on the roads is the biggest factor in what can cause breakdowns. Flats will be much more frequent with this unless you get a more durable tire as well as bigger. A good tire is going to be the biggest deterrent to flats along with keeping enough air in your tires to help prevent pinch flats. Two potential additions to new tires to further help prevent flats are tubeless tires with sealant and thorn proof tubes which are tubes with thicker rubber.

Winter Additions For You Bike

During the summer months the bike is generally stripped down to be the lightest and fastest possible. During the winter, however, it’s highly unnecessary as well as much less functional. Having a few add-ons to the bike will keep you more comfortable, safer, as well as get you out of a situation you would otherwise be stuck on the side of the road with.

Fenders

Fenders

Even on warmer days as the snow melts, if that’s a thing in your area, the roads are probably still going to be wet. Having fenders will not only keep you dry but will also keep your bike cleaner. In many areas around the country you not only need fenders on group rides, but also a “buddy flap” which is essentially a mud flap that hangs off your rear fender preventing wheel spray into the rider behind you.

Lights

With the shorter amount of daylight, having lights permanently mounted on your bike for when it does in fact get dark or even if it’s just starting to, is more than a good idea and could potentially be a lifesaving decision. In winter in a lot of areas, drivers aren’t always looking for cyclists so even if it’s just starting to get dark, it’s a good idea to turn them on.

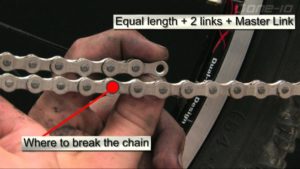

Chain Tool

Even with a new chain, they can still break, particularly if you get snow packed into your cassette. Many multi-tools come with a chain-tool that can be used to take out the broken link and shorten the chain to make it home.

Pump

Another valuable addition to your winter setup is a pump instead of CO2 cartridges. With CO2 you only get one try with each and ifit doesn’t work, that’s it. During winter especially, the valve can become frozen while open, letting out all the air you just put into the tire.

Extra Tube

With all the grit on the roads, flatting is an increased possibility and thus having one extra tube might not be enough. Bringing a second or third one can give you piece of mind to keep riding longer on your original route instead of just looking to make it home.

Insulated Bottles

Although separate from your bike, having insulated water bottles will keep you warmer on the road by keeping your liquids from freezing solid as quickly. Put warm water in them when you start and make sure you close the top to push any liquid out that can get trapped in the opening to keep it from freezing shut.

Riding in winter does require more dedication and planning, but if you take the necessary steps to make sure you’re prepared along with your bike, it will keep it fun and enjoyable like every ride should be. Stay ahead of the curve on winter and your rides will stay pleasant and enjoyable all the way until spring.

Lets face it: Tubeless is annoying to set up without a compressor. Thankfully

Lets face it: Tubeless is annoying to set up without a compressor. Thankfully

chainring, and the rear to the smallest.

chainring, and the rear to the smallest.

Begin threading the new pedals on with your fingers, making sure you’re turning the right way. If it’s resisting don’t force it, as the pedal should go on smoothly with very little resistance. Turn the right pedal clockwise to tighten, and the left counterclockwise.

Begin threading the new pedals on with your fingers, making sure you’re turning the right way. If it’s resisting don’t force it, as the pedal should go on smoothly with very little resistance. Turn the right pedal clockwise to tighten, and the left counterclockwise.