Friction has always been the best way to stop a moving object. Brakes create that friction. Today’s bicycle disc brakes are a modern marvel of refined, contemporary engineering. It provides cyclists with confidence and reliability. Is it for everyone? The answer lies in what you expect from a disc brake and how well you maintain it.

History of the Bicycle Disc Brake

It was the mid 1970’s; the mountain bike had not yet reached any kind of popularity and almost every bike was a road bike with rim brakes. Disc brakes were nothing new though, as they had been on cars for many years. In about 1975, the first disc brakes were placed on a road bike — but it didn’t stay there long.

Sacrifice and Benefit

Rim brakes worked just fine. They were lighter, less expensive, easier to work on and bike shops or sporting goods stores had parts for them. In short, the benefits of the disc brake were outweighed by sacrifices as far as road bikes of the 70’s were concerned. The real need for a disc brake didn’t exist until the introduction of the mountain bike a decade later.

Application of the Disc Brake

The difference is in the application. Mountain bikes rely on disc brakes not because they work better — but because they work better on mountain bikes. Mountain bikers prefer disc brakes for obvious reasons. They can bash their rims out of true and the brakes don’t rub. They can ride through mud, sand or grime and the brakes don’t clog up. There’s no issues with pebbles getting stuck in brake pads and damaging the rims. When it’s wet, the pads still grab almost as if it were dry.

More Stopping Power

Disc brakes, and especially hydraulic disc brakes, do provide more stopping power than rim brakes. However, a feather-light rim brake has more than enough stopping power for a typical rider on a road bike and disc brakes add weight. Most road riders want to go faster, not stop better.

Bicycle Rim Brakes

Rim brakes work by means of generally a rubber compound brake pad, attached to the bike’s frame, positioned directly over the rim of the wheel. When the brake lever is squeezed, the pad pushes against both sides of the rim generating friction to slow the bike down and bring it to a stop.

Bicycle Disc Brakes

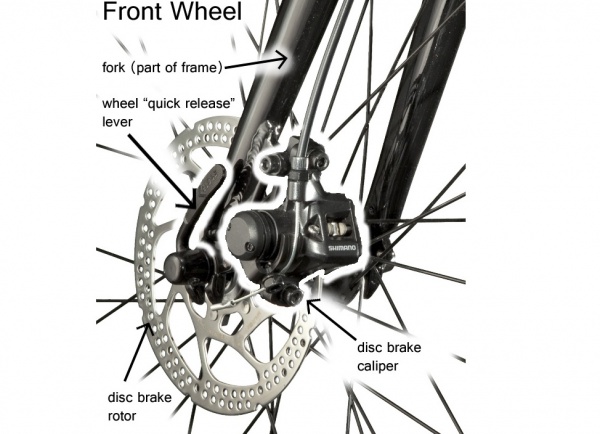

The rotor — the shiny disc on a disc brake setup — spins with the wheel. Calipers are attached to the fork and rear stays of the bike and are equipped with the brake pads. When the brakes are applied, the calipers squeeze the pads against the disc instead of the rim.

Disc Brake Advantages

- Work if your rim is bent or damaged

- Don’t wear rims out

- Work better in wet, dirty, and muddy conditions

- Rotor is easy to replace when worn or damaged

- More stopping power

- Look cool

Rim Brake Advantages

- Weigh less than rim brakes

- Lower cost

- Longer pad wear, more pad options, easy to replace

- Parts are cheap and available everywhere

- Offer better finesse in stopping particularly advantageous in cyclocross

Cable Actuated versus Hydraulic Disc Brakes

Disc brakes come in two varieties; cable actuated or mechanical, and hydraulic.

Cable Actuated

Mechanical disc brakes rely on cables and housing like a traditional rim brake. Bike companies often use cable actuated disc brakes for simplicity and serviceability. Mechanical disc brakes are much less expensive than hydraulic brakes. The biggest downside is how hard you have to pull the brake lever compared to a hydraulic lever for the same amount of stopping power.

Hydraulic Disc Brakes

Hydraulic disc brakes don’t use cables but instead use fluid-filled chambers and tubing — similar to the brakes on your car — to push brake fluid. Brake pads are housed in the caliper and are forced into the rotor by hydraulic fluid. Because hydraulic fluid does not compress or flex like a cable, hydraulic systems are considered higher performance than mechanical systems and offer better, seamless stopping power.

Cable vs. Hydraulic Servicing

Hydraulic disc brakes are more difficult to service than cable actuated disc brakes. If you develop a fluid leak in a hydraulic line or fluid chamber out on a ride, brakes can begin to fade and at some point fail. There’s no way to fix them on the road or trail. Servicing hydraulic brakes can be an expensive procedure that can require a professional if you’re not mechanically inclined to do it yourself.

Disc Brake Maintenance

There are too many varieties of disc brakes for a single generic maintenance chapter — but they all require similar maintenance procedures. Consult your manufacturer’s suggested maintenance procedures for your specific disc brake.

Warped Rotor

The disc brake rotor is a crucial part of the system. It must be perfectly flat and straight to work properly. If it’s bent or warped it either will need straightened to not rub on the pads or will need replaced altogether.

Bleeding Lines

Replacing Fluid

DIY Bleeding or Replacement

Caliper and Pad Adjustment

Pad Replacement

Generic Pad Removal

Additional Cable Adjustment

Give it a Checkup

- The rotor must be straight and smooth

- The caliper mechanism must be properly aligned with the rotor

- Pads must be positioned correctly in the caliper

- There must be enough “pad” left to adequately stop the rotor before any damage occurs

- The lever mechanism– cable or hydraulic — must push the pads tightly against the rotor with “lever” to spare, ie. the lever doesn’t pull all the way to the handlebars