Tubeless tires have been a mainstay of the mountain biking world for years, and have inevitably made their way into road cycling as well. With mountain biking, tubeless tires allow riders to run their pressure much lower, providing enhanced surface area and grip without the risk of pinch flats. Road tires, however, are more efficient when run at a higher pressure, so what is the benefit of going tubeless?

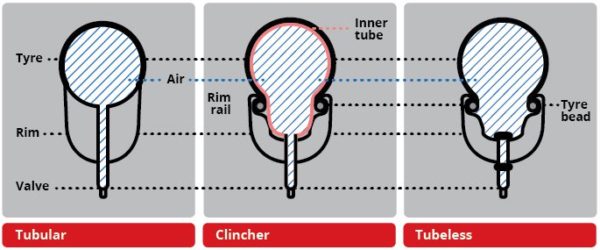

Traditionally there have been two main options for road cycling tires: clincher and tubular. Clinchers are the best option for the majority of riders, as they are easy to use and fix by swapping out or repairing the inner tube. Tubular tires are lighter and are used by a lot of racers, but unless you have a support vehicle following you on every ride, then replacing a tire is a painfully long and technical process.

Now there is a third option with tubeless tires, but are they worth the leap?

How do tubeless tires work?

As the name suggests, tubeless tires do not have an inner tube, and are setup similar to a car tire. The open rubber tie sits firmly on the wheel’s rim, with the air sitting in the cavity between the rim and inside of the tire. In addition, a liquid sealant is used inside the tire to preemptively plug any small cuts in the tire without losing pressure at all.

Tubeless wheel setup

The nice thing about tubeless wheels is that they can be used with both a tubeless tire and the typical clincher (inner tube) setup. The shoulder in the inner rim will have a much more pronounced recess that the tire bead fits securely into (see diagram), rather than the traditional U-shaped rim bed on clincher wheels.

Tubeless tires themselves are designed with a tougher bead to provide an immediate seal with as perfect airtight fit. If you try to fit a tubeless tire on a clinched rim, it will come off as you add pressure.

Are tubeless tires worth it?

Pros

- Speed – clincher tires have a level of friction between the tube and the tire that tubeless tires eliminate, lessening rolling resistance and making them faster.

- Less flats – The tubeless setup rules out pinch flats completely, and dramatically lessens the danger of blowouts with the liquid sealant. This has a huge impact on the number of flats you’re likely to experience. Plus, if you do have a flat out on a ride that the sealant can’t handle, you can use a tube to get you home.

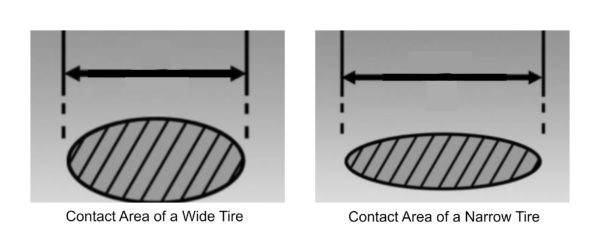

- Comfort – Tubeless tires can be run at a lower pressure (dropping about 15-20 psi) without sacrificing performance. This can enhance your corner grip, traction, and overall comfort. You can even venture off road with the tires being a lot more forgiving than if they were running at full pressure.

Cons

- Difficulty in fitting – As a system that depends on tight seals and high pressure, installing or removing the tire can be a difficult and frustrating job. So, while the likelihood of flats may be reduced, the process to fix it in the case of total failure can leave you swearing on the side of the road. You may even need an air compressor to get a proper seal.

- Weight – Tubeless tires are largely heavier than a clincher setup, with thicker sidewalls that add weight.

- Racers don’t use them – This may or may not matter to you, but racer’s do not use tubeless because of the added weight with minimal gain. However, for the recreational cyclist, the lower risk of flatting may be worth the sacrifice.

Tubeless tires are by no means taking over the roading cycling world (as they have with mountain biking), but as technology advances we may see them grow in popularity. Having tubeless-ready wheels is a great way to go, as it leaves the choice up to you whether you want to stick with clinchers or give tubeless a try.

Lets face it: Tubeless is annoying to set up without a compressor. Thankfully

Lets face it: Tubeless is annoying to set up without a compressor. Thankfully